According to the Regulation of the Minister for Labour and Social Policy of 26 September 1997 on general occupational health and safety rules, as amended (consolidated text: Journal of Laws of 2003, no. 169, item 1650) work at a height is a work performed in the area situated at least 1.0m above the floor or ground.

In case collective protective equipment, such as scaffolding, protection grids, jacks, elevators etc., cannot be used it is necessary to use personal protective equipment.

The selection rules for fall protection equipment are specified in EN363 standard “Personal fall protection equipment - Fall protection systems”.

Personal fall protection systems are composed of three basic elements:

- anchorage (catch element) - defined in EN795 standard,

- connector and shock absorber lanyard - defined in EN355, EN362 and EN354 standards,

- safety harness to which EN361 and EN358 standards refer.

Remember!

Careful selection of adequate fall protection systems and compliance with applicable rules guarantees your safety!

Anchorage should be placed steadily on a load-bearing structure at the workplace to enable attaching connector and shock absorber lanyard.

Connector and shock absorber lanyard is a combination of straps with an anchorage point which the user wears. Its aim is to alleviate the effect of falling by absorbing the kinetic energy which is produced during the fall.

Safety harness - elements of the protective system which the user wears. It is supposed to distribute the forces which act upon the body during falling and shape the body into a proper position during and after falling.

To protect the equipment against damage resulting from high temperatures (or as a result of energy produced during falling) the elements of the equipment have to be resistant to heat. The entire equipment has to be inspected according to the guidelines of the producer.

Safety instructions for the use of personal fall protection equipment

Personal fall protection equipment is used when no other protection measures can be implemented.

The aim of such equipment is not to prevent the fall but to eliminate the effects of the fall, i.e. a safe arrest of the falling person and alleviation of the consequences of sudden loss of speed.

To fulfill its job and provide appropriate degree of protection, the personal protection system must be configured with the following factors in mind:

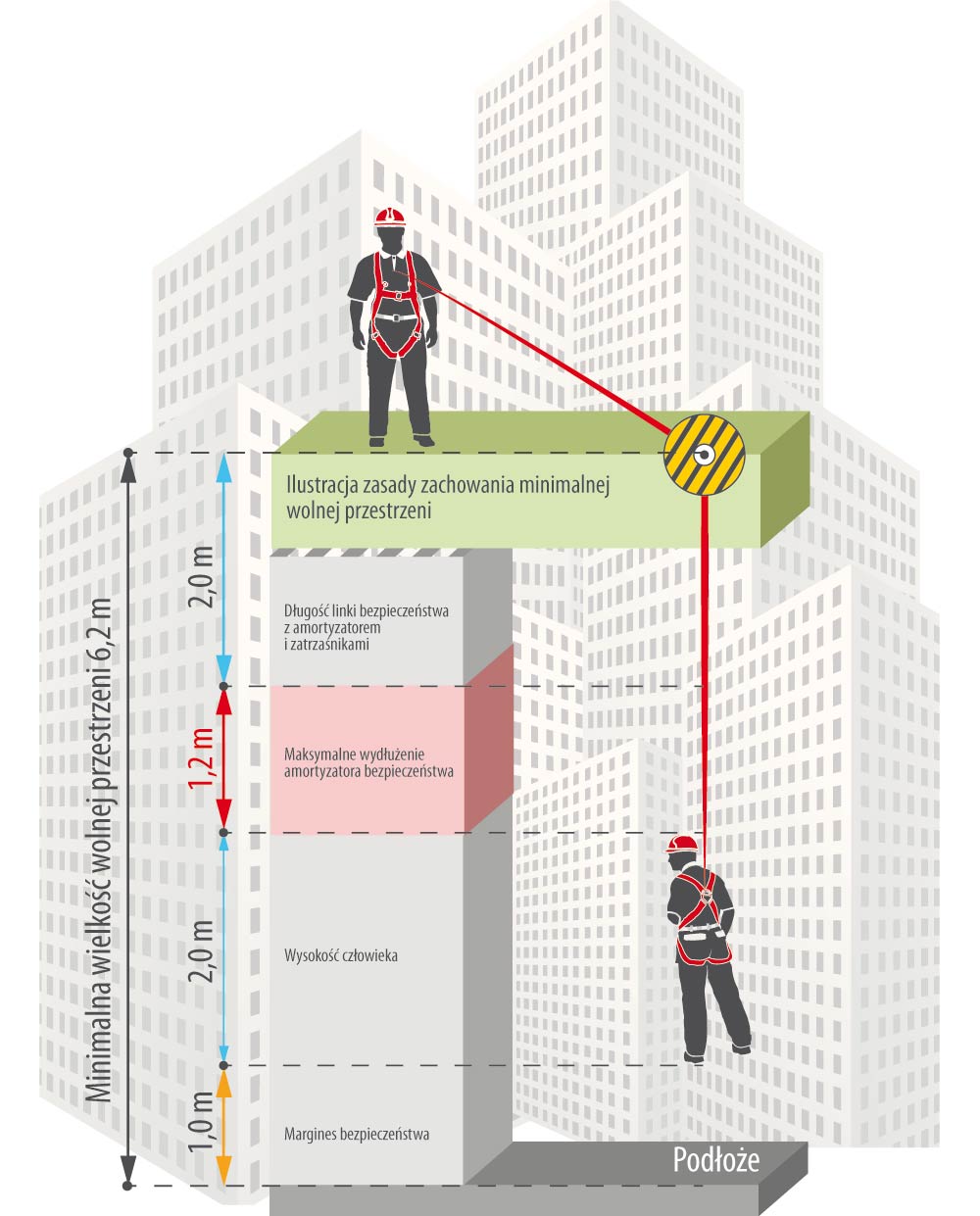

Minimum free space

A safe fall arrest must happen in the air - before reaching the ground, construction elements or other obstacles (after the so-called free fall phase).

It should be remembered that if the falling person hits the ground or any obstacles the effects will always be dangerous to health and life.

To eliminate such risk and avoid such danger a so-called free space should be provided below a worker within the space of potential fall.

When determining the size of the free space one should take into consideration the parameters of the connector and shock absorber lanyard and the distance between the anchorage point and the user.

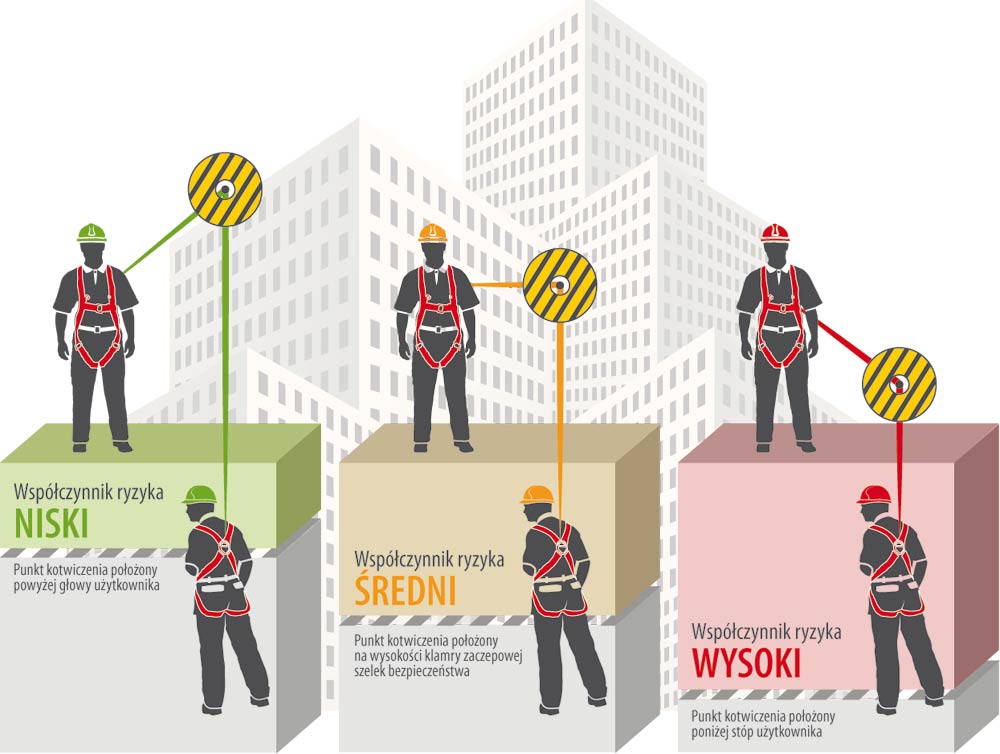

The location of anchorage point

It should be remembered that the free fall path, i.e. the path from the point of falling off to the point where protective equipment acts, should be as short as possible.

The height at which the anchorage point is located determines the length of this path. If the anchorage point of the connector and shock absorber lanyard is situated above the worker, the free fall path will be reduced to a minimum - it is an advised location of the anchorage point.

If the anchorage point is situated below the worker the path of falling is longer which makes it necessary to provide larger free space, otherwise there is a risk of hitting the ground or an obstacle on the way.

Moreover, long falling path may contribute to the risk of surpassing the forces associated with a fall arrest event.

This is why it is advised to place the anchorage point as high as possible.

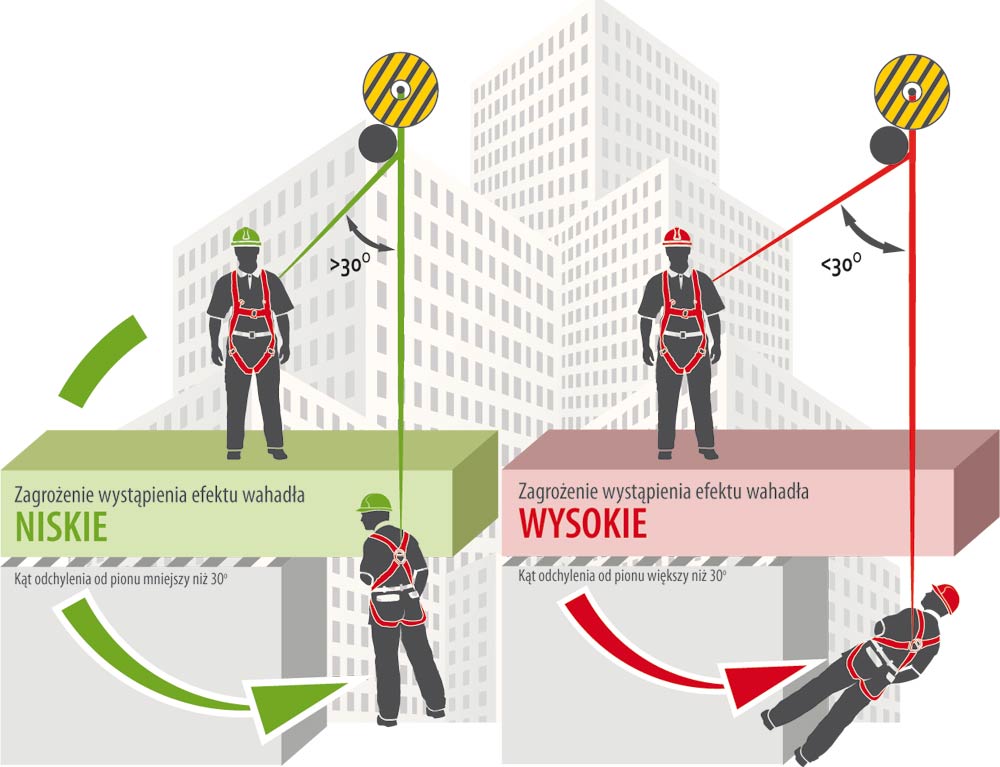

The pendulum effect

The pendulum effect is a dangerous side effect of falling. It consists in the pendulous nature of the free fall which creates the risk of hitting obstacles situated on the sides.

Moving away from the vertical line leading perpendicularly from the anchorage point to the ground increases the risk of pendulum effect.

Additionally, one should take into consideration that the pendulum effect may affect the efficiency of various connector and shock absorber lanyards - e.g. fall arresters.

This is why, one should aim to reduce the risk of pendulum effect and if it is necessary to move horizontally within a large space, the anchorage point should be frequently changed.

Technical inspection

The connector has to be subject to periodic inspections as the safety of the user depends on the efficiency and durability of the equipment.

The inspection should be carried out at least once a year.

The inspection has to be conducted by a specialist according to strict procedures.

The inspection involves verification of the readability of marking.

The user is obliged to update the service card with required data.

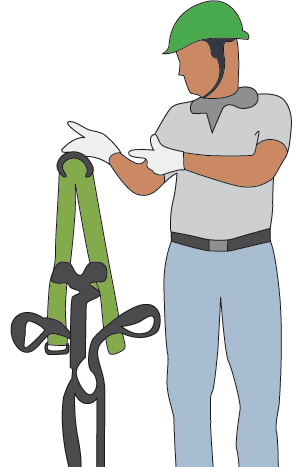

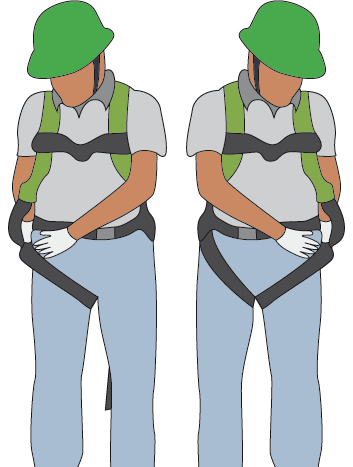

Putting on straps

List of standards for fall protection equipment

EN1496

Rescue equipment. Rescue lifting devices.

The standard specifies requirements, test methods and marking, as well as information to be provided by the producer concerning rescue lifting equipment. According to the European standard rescue lifting devices are a part of rescue equipment.

Attention: Rescue lifting devices compliant with EN1496 standard may constitute a part of other rescue systems: descender devices (EN341), fall arresters (EN360) and others.

EN1497

Personal fall protection equipment. Rescue harness.

The standard specifies requirements, test methods, marking rules and information that has to be provided by the producer concerning rescue harness. According to the European standard, rescue harness is an element of the rescue equipment.

EN1891

Personal fall protection equipment. Low stretch kernmantle ropes.

EN353-1

Personal fall protection equipment. Guided type fall arresters with a rigid anchor line.

The standard specifies the requirements, test methods, marking and information that has to be provided by the producer, as well as the packaging method concerning guided type fall arresters with a rigid anchor line.

EN353-2

Personal fall protection equipment. Guided type fall arresters with a flexible anchor line.

EN354

Personal fall protection equipment. Lanyards.

This standard specifies the requirements, test methods, marking rules, information that has to be provided by the producer and packaging method concerning lanyards with a length adjustment device.

EN355

Personal fall protection equipment. Shock absorbers.

This standard specifies the requirements, test methods, marking rules, information that has to be provided by the producer and packaging method concerning shock absorbers.

EN358

Personal fall protection equipment with work positioning systems. Work positioning belts and lanyards which limit changes of position.

This standard describes belts and lanyards designed for work positioning or limiting the changes of position. The standard provides requirements for design and structure of the hip belt, work positioning lanyard, connectors and fire resistance.

EN360

Personal fall protection equipment. Fall arresters.

The standard specifies requirements, test methods, marking rules and information that has to be provided by the producer concerning fall arresters.

EN361

Personal fall protection equipment. Safety harness.

This standard specifies the requirements, test methods, marking rules, information that has to be provided by the producer and packaging method concerning the safety harness.

EN362

Personal fall protection equipment. Connectors.

This standard defines requirements, test methods, rules for creation of manual instructions and marking rules concerning connectors. It specifies the requirements for design and ergonomics, materials and construction, resistance to dead load and corrosion. It also provides the methods of testing the resistance to dead load and corrosion.

EN363

Personal fall protection equipment. Fall protection systems.

The standard defines the terminology and basic requirements for fall protection equipment which is used as personal protection against fall from height.

When selecting protective equipment one should take into consideration the following factors:

- Location of existing anchorage points to which the protective devices may be attached. If the existing anchorage points are not accessible, one should consider the possibility of installing anchorage sets,

- The height of space free from any construction elements below the worker - it determines fall height,

- Space free from construction elements where a controlled fall may occur - a worker may swing like a pendulum,

- The space in which a worker is likely to move and type of movements a worker is likely to make,

- Work time at a given work position,

- Worker’s physical and mental aptitude,

- Additional factors which could influence the correct operation of the system, such as: contact with dust, oil, low or high temperatures, molten metal splashes, chips from cutting processes, potentially dangerous construction elements with sharp edges etc.

EN364

Personal fall protection equipment. Test methods.

This standard describes test methods for individual fall protection devices protecting against fall from height. The standard also provides a description of apparatus for conducting the tests.

EN365

Personal fall protection equipment. General requirements for instruction manuals, maintenance, periodic technical inspections, repairs, marking and packaging.

This standard defines the marking symbols which should be placed on fall protection equipment, as well as the obligatory content of instruction manuals.

EN795

Classification of anchor systems

| A1 | It is not a personal fall protection device. It consists of anchorage points designed to be placed on vertical, horizontal or sloping surfaces (walls, columns, lintels) |

| A2 | It is not a personal fall protection device. It consists of anchorage points designed to be placed on sloping roofs |

| B | It is a personal fall protection device. It consists of temporary anchor devices which can be deconstructed and transported |

| C | It is not a personal fall protection device. It consists of anchor devices with flexible horizontal anchor lines, the so-called life lines. Acceptable inclination angle 15O |

| D | It is not a personal fall protection device. It consists of anchor devices with rigid horizontal anchor line in the form of a rail |

| E | It is a personal fall protection device. It consists of deadweight anchors to be used on horizontal surfaces. Acceptable inclination angle 5O |

Fall protection equipment - Anchor devices. Requirements and tests.

This standard defines the requirements, devices suitable for static and dynamic testing of anchor systems, test methods, instruction manuals, marking, labeling and packaging of anchor devices used alongside personal fall protection equipment. It also contains recommendations as to the installation of anchor systems.

The anchor system should be installed on a load-bearing construction at the workplace to enable the attachment of connector and shock absorber lanyard. One may use elements of positions of work at a height, such as a bearing beam, steel profiles and other stable construction elements.

Anchorage point on a load-bearing construction must be able to bear a load of at least 15kN and be adjusted to a given connector and shock absorber lanyard. If there is no suitable area within the work position, it has to be constructed.

EN813

Personal fall protection equipment. Sit harness.

This standard specifies the requirements, test methods, marking and information to be provided by the producer for sit harnesses suitable for use in work positioning systems and preventing falls which require low catch point.

Attention: Sit harness is not suitable for fall arrest purposes.